There are no shortcuts to perfection.

CamPro’s research and development department boasts more than 90 cumulative years of experience and expertise in helping you make the shot. Each year, over 5000 hours are attributed to R&D. This sustained investment is used to further our fundamental know-how as well as improve our projectiles and manufacturing process.

We also work very closely with our clients on R&D projects. This way, we can meet clients’ expectations, because of our razor-sharp focus on details and understanding of distinct customer needs. We can design custom bullets as well and we are willing to embark on exclusive partnerships with our clients. After all, our goal is a win-win relationship for all parties. Don’t hesitate to contact us for your requests; we will evaluate them in a confidential and professional manner.

Throughout our entire product portfolio, you will find projectiles that are the result of substantial R&D efforts, such our 10 mm/40 165 gr SH and 10 mm/40 180 gr SH, SOCOM projectiles, and black powder bullets.

Experience the advantages of CamPro projectiles.

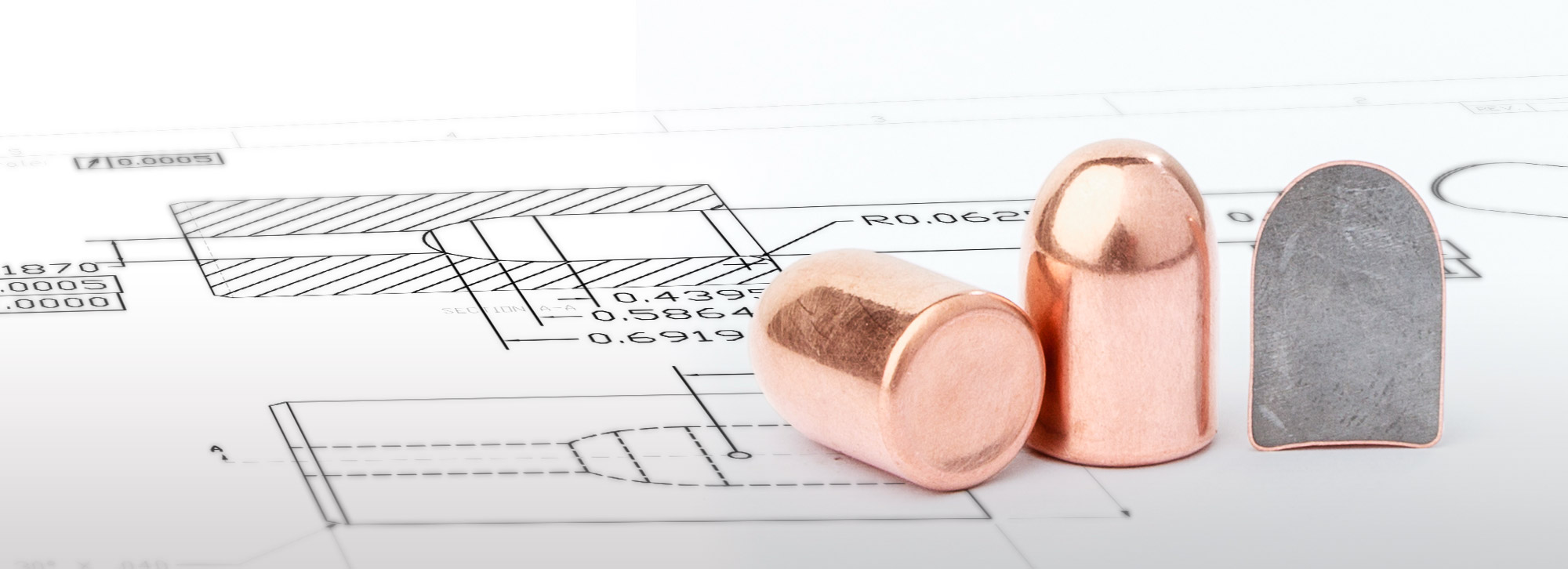

- Full copper plated

- 0.008” (203 μm) thick copper layer

- Allows the safe use of magnum loads. No grease needed!

- Reformed at the end of the process for an ultra-precise shot

- Composed of 98% lead and 2% antimony

- Swaging leads to a greater weight uniformity

- Can be used with standard reloading charts for jacketed bullets

- Complete traceability system for maximum quality control

- Cleaned and polished before shipping

Discover our complete line of first-rate bullets or contact us today for custom jobs—confidentiality guarantee!